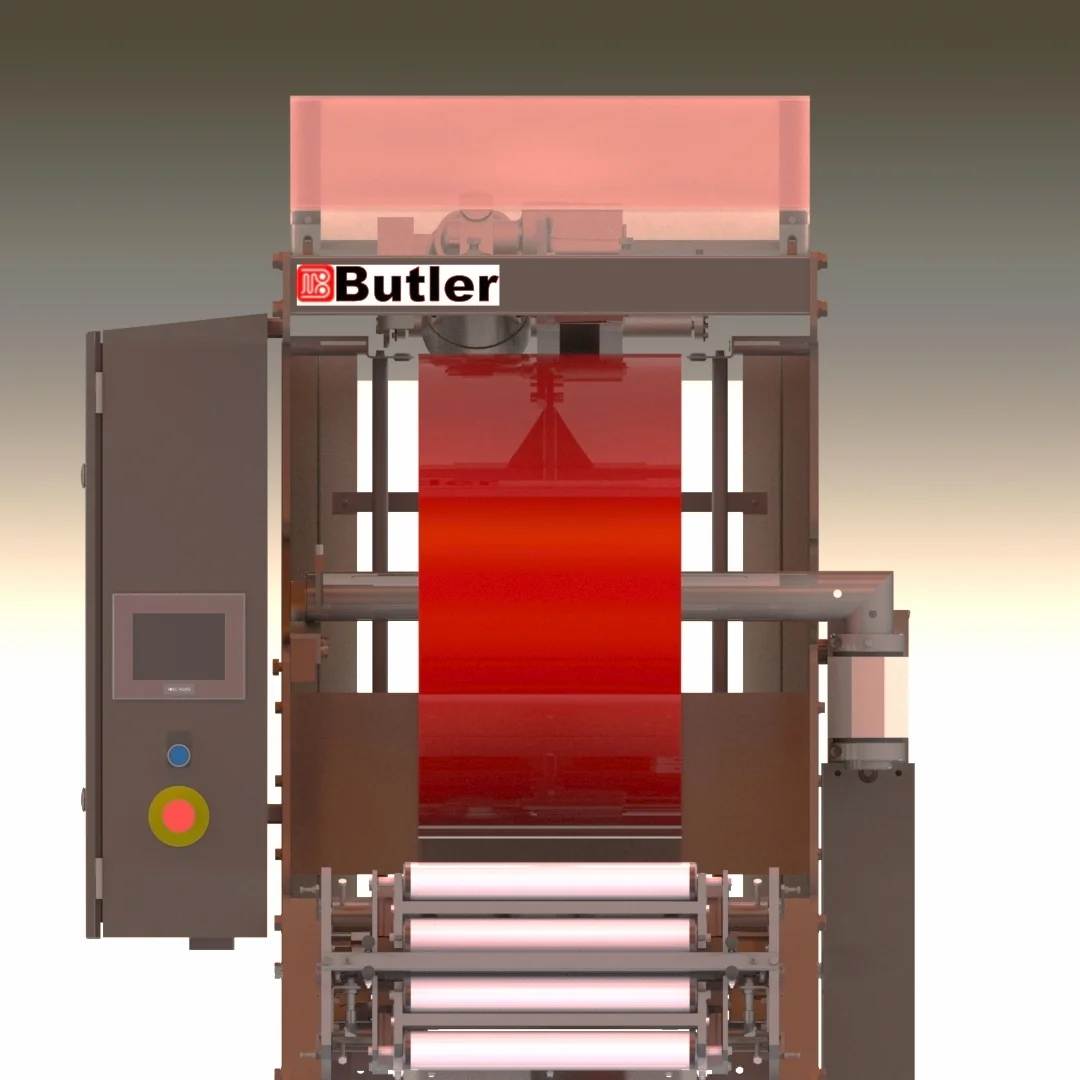

The SP1 offers a compact and highly efficient automatic splicing solution for a variety of packaging processes, including vertical form fill seal (VFFS), horizontal form fill seal (HFFS), and overwrap machines. The SP1 is simply designed with easy to replace wear parts and provides a very fast ROI.

Automatic Splicing

After the operator has prepared the splice, the SP1 will continuously monitor the running roll of film and automatically fire the splice before it fully expires.

The SP1 can be equipped with three different end of roll sensing systems depending on your particular film and core. The end of roll sensor system triggers the splice, leaving a minimum amount of unused film on the expired roll.

After the splice has occurred, the expired roll is removed, a new roll is loaded, the new splice is set up, and the cycle is repeated, all without ever stopping production.

Splice Heads

The SP1 can be configured with three different types of splice heads, all producing a butt splice. The three types of heads are; the standard splice head, the tape two sides splice head, or the heat seal splice head. In both the standard splice head and the tape two sides splice head, a vacuum system holds the end of the stand-by roll firmly so the operator only needs to tape one side of the web and close the splice head. The heat seal splice head does not require a vacuum or tape - a clamp bar holds the new web in place until the seal or cut is made.

This simple, one-step operation minimizes the chances of splice failures due to human error, enabling the SP1 to perform with over 99% splice reliability.

Assisted Roll Lifting

The standard SP1 features swing-out shafts for easy direct front roll loading and a compact footprint. To make loading even easier, the SP1 can be equipped with two different lifting mechanisms.

The top shaft can be configured with the Easy Lift, a pneumatic elevator that lowers the upper roll shaft to a more accessible height, making it possible to load rolls quickly and with less effort.

Alternatively, a Direct Load hoist can be installed on top of the machine, eliminating the need for any external roll lifting equipment.

Configurations and Options

The SP1 is designed to be highly configurable in order to fit each end user's needs. Butler builds each SP1 to the dimensions of the film rolls that will be run on it in order to minimize costs and maximize the Return on Investment. The SP1 can also be equipped with a wide variety of options to maximize performance and meet the unique requirements for each application and plant.

Quick Facts

Common applications: VFFS, HFFS, Over Wrapping, Thermoforming

Diameter sensing splice actuation is standard

Standard models available for roll widths from 13 in (33.02 cm) to 35 in (88.9 cm)

Custom models available for roll widths up to 46 inches (116.84 cm)

Maximum roll diameter: 24 in (60.96 cm)

Maximum roll weight: 275 lbs (124.738 kg)

Height: 87.5 in ; Depth: 47.3 in (120.142 cm)

Max web speed: 600 fpm (182.88 m/min)

Typical Web Tension: 0.1-0.25 lbs (.045-.11 kg) per linear inch (pli)