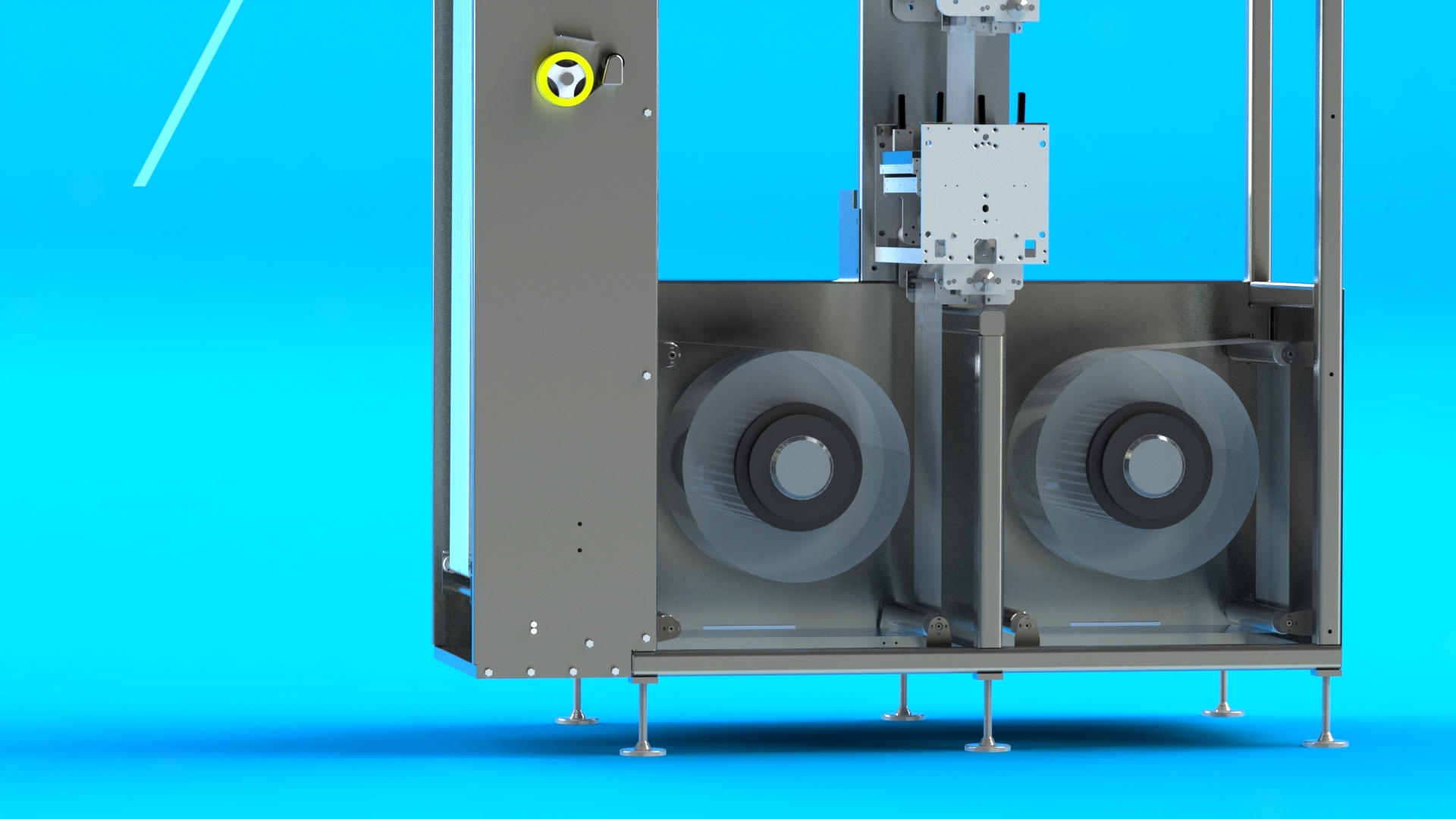

The SP3 offers a compact and highly efficient automatic splicing solution for a variety of high-speed packaging processes such as heat-shrink sleeving or narrow web applications. The SP3 uses core drives to feed material into the system.

Direct Front Roll Loading

The SP3 features cantilevered roll shafts that allow for a simple and quick loading process.

Due to the low height of the roll shafts, the rolls can be simply lifted and mounted directly from the front of the machine. An air shaft system is used to secure the rolls in position.

By default, the SP3 is equipped to handle rolls with a 5 in ( 12.7 cm) core, but adapters can be acquired to accommodate any core size larger than that.

Automatic Splicing

After the operator has prepared the splice with the beginning of the new roll of film, the SP3 will continuously monitor the running roll of film. When the running roll approaches the end of the roll, the SP3 will stop the running roll and fire a splice, while the integrated accumulator supplies the process.

The SP3 can also splice the new roll "in registration" with the old roll to ensure that your sleeves are "in registration" before and after the splice.

After the splice has occurred, the expired roll can be removed and the cycle restarted, all without ever stopping production.

One Step Splice Head

The SP3 Splice Head was designed to be as easy to use as possible, allowing splices to be prepared in under two minutes.

A vacuum system holds the web of the idle roll firmly so all the operator needs to do is place a strip of tape on each side of the splice head and then close it. This simple, one-step operation minimizes the chances of splice failures due to human error, allowing the SP3 to perform with over 99% splice reliability.

The SP3 splice head performs a butt-splice, with tape applied to both sides of the film, ensuring a strong and secure splice joint.

Configurations and Options

The SP3 Sleeving Machine is designed to be configurable to fit each end user's needs. Butler can configure our SP3 SL to meet different core and OD dimensions of your film rolls. The Butler SP3 SL can operate at speeds up to 500 fpm (152.4 m/min).

Quick Facts

Common applications: heat-shrink sleeving

Handles narrow rolls with ranging from 2 to 13 in (5.08 cm to 33.02 cm) in width

Maximum roll diameter: 22 in (55.88 cm)

Maximum roll weight: 30 lbs (13.6 kg)

Maximum web speed: 500 fpm (152.4 m/min)

Maximum web tension: 1 - 1.5 lbs (.45 kg - .68 kg) of total web tension

Dimensions: 71.33 in (181.17 cm) x 92.81 in (235.73 cm) x 36.50 in (92.71 cm)

Weight of splicer: 1100 lbs (498.95 kg)